Compound.

Extrude.

Innovate.

Highland Plastics specializes in custom compounds and extrusion.

Delighting our customers since 1991.

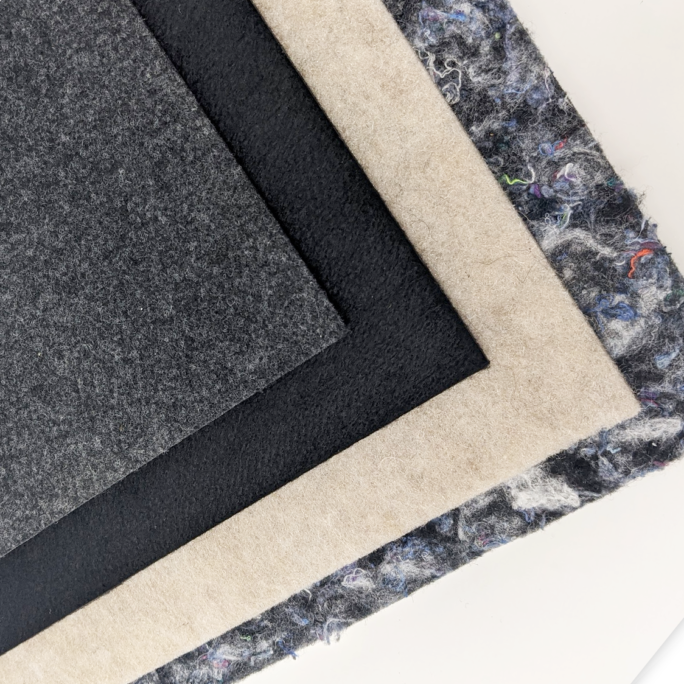

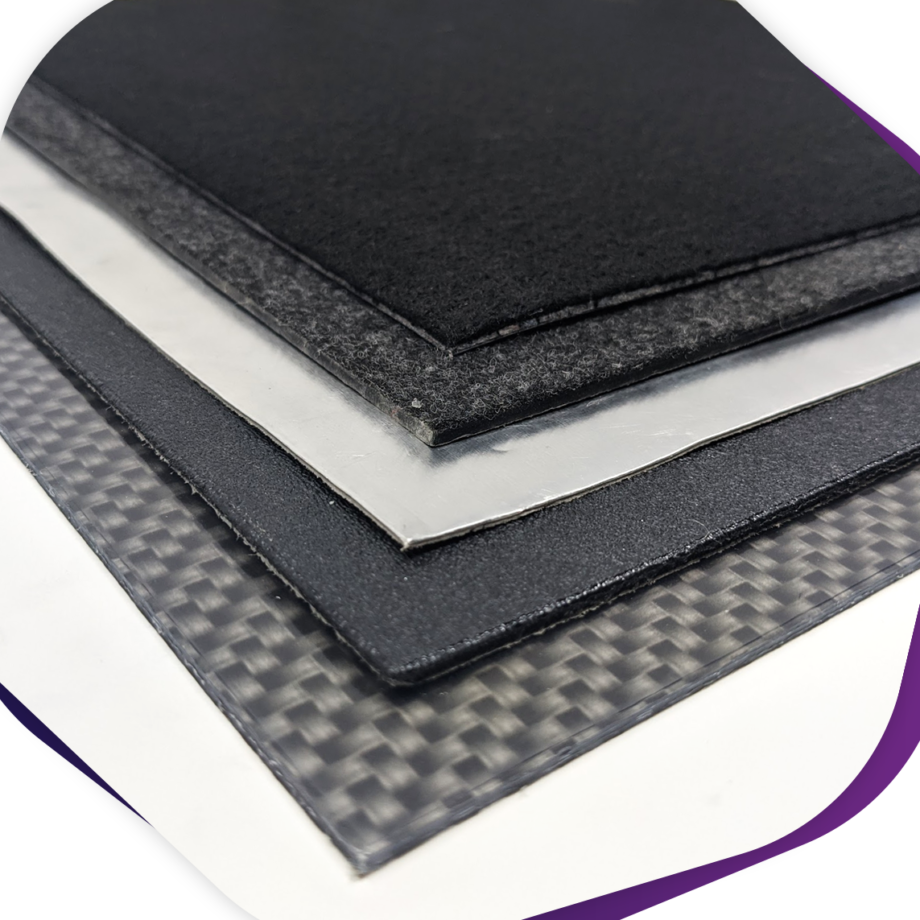

Lamination Capabilities

We have experience laminating a wide range of materials, including carpet, foam, foil, films and engineered plastics.

Prototypes & Sample Runs

Do you need an R&D partner to convert your resin? We can design an economical trial schedule to meet your needs.

Mass Loaded Materials

Our highly filled acoustic mass barriers are suitable for both automotive and non-automotive applications.

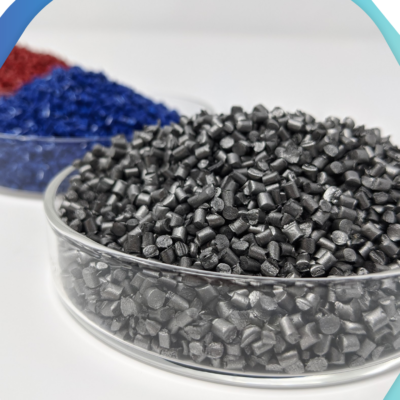

Custom Compounding

Let us develop a formulation specific to your application.

Program Recycling

Die-cutting or thermoforming? We can buy back and recycle your scrap material, reducing your program’s waste.

Need Advice Choosing Suitable Materials?

We would be happy to talk to you about your specific plastic needs. Whether you are trying to create a material to a known industry specification or want to create something that hasn’t been done before—we can suggest a product construction that makes sense for your application.

The Perfect Blend of Expertise in Materials and Manufacturing

Compounding

Our compounding abilities let us fine tune a formulation specific to your application. Give yourself an edge on your competition by developing a material with unique characteristics.

Extruding

Our extrusion technology supports a wide range of product constructions. From delicate multilayer lamination, to crumb rubber conversion, to resin casting in molds—we can do it all.

Materials We Regularly Manufacture Include:

Flame Retardants

Acoustic Barriers

High Service Temperature Plastics

Thermoplastic Olefins, Elastomers and Vinyls

What Can We Help You Solve Today?